Posted Thu, Sep 27, 2018

in

The key to communicating your product effectively to your pattern maker, sample maker and especially to your factory, is having a detailed and easy to understand Tech Pack. Communicating your message visually is effective both to bridge potential language barriers, as well as to save someone time in reading and referencing your tech pack, ensuring that the information is actually seen, understood, and utilized during production and product development.

Once you have your design sketch prepared, you'll want to make call-out's for what seam finishing and construction methods are needed for your product. Many designers out there may or may not know the name of the stitch, or what machine does it. Even if you do, communicating your needs visually will ensure that you achieve the results you are looking for. I am happy to share a great resource that can help you do this - ABC Seams!

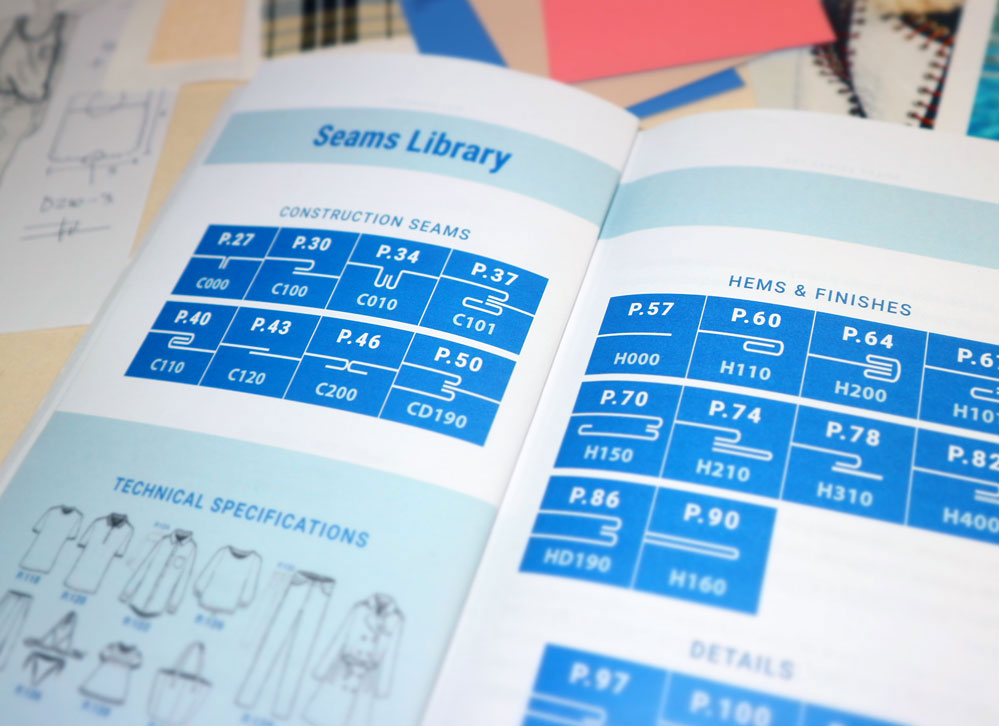

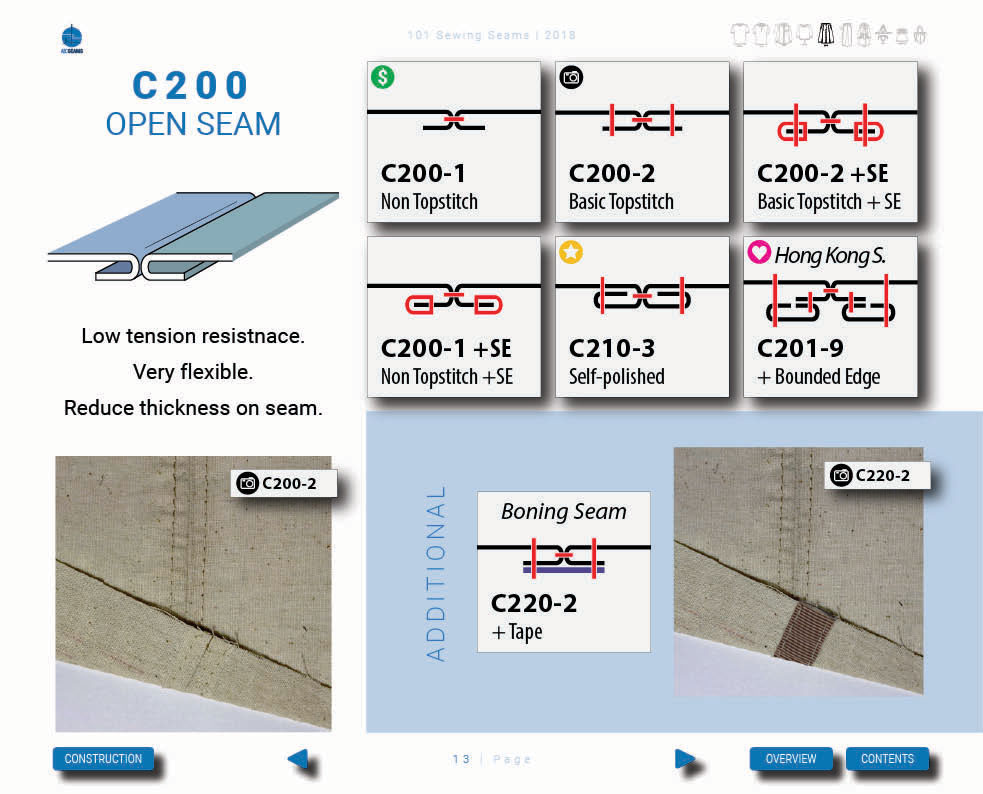

ABC Seams is a company based in Australia who I found and be-friended via Instagram. I was delighted to see them launch their e-book earlier this year, 101 Sewing Seams. The book is broken down into 3 simple categories: Construction, Hems and Finishes, and Details. From there the seams are grouped into similar structure or style and contain multiple options. What's great is that each seam is illustrated both technically and paired with an image to show the seam on fabric. It's easy to take a look at your own clothing or reference samples and compare physical seams to ones listed in the book, to find what will work best for a style you are developing.

Some of the advantages of using this code system:

Using a proper vocabulary and pairing that with the visual images will help you to get better results when working through product development, pre-production and production.

- get better results in a shorter period of time

- reduce development costs

- improve working relationships

I started with the e-book, which I utilize as a reference, but also to take screen shots of the seams to include in my tech packs (which I build in Excel). However, I also purchased the print version when it became available, and enjoy using it as a resource during client meetings to help them to identify stitches and make decisions. Depending how you like to work, you might enjoy having both versions, or just the digital copy.

ABC Seams also offers a membership to their site - and there's a FREE version! Membership includes free access to the Seams Gallery to refer at any time, which can be used to explain your designs clearly, and be more creative when designing. You will also receive a monthly email with the latest updates to the Seams Gallery (new seams), and interesting resource files to download. Joining also gives you a discount on the e-book, so I suggest doing that to take full advantage.

I'm excited to be able to offer a discounted rate on the e-book for my readers here, thanks to Belu at ABC Seams!

[content_box]

101 Sewing Seams E-Book €8

Buy Now €8

Buy Now €8

JOIN ABC SEAMS FREE MEMBERSHIP, then:

Buy the eBook with 30% discount here. (€5)

JOIN ABC SEAMS FREE MEMBERSHIP, then:

Buy the eBook with 30% discount here. (€5)

[/content_box]

The print copy is available on Amazon: